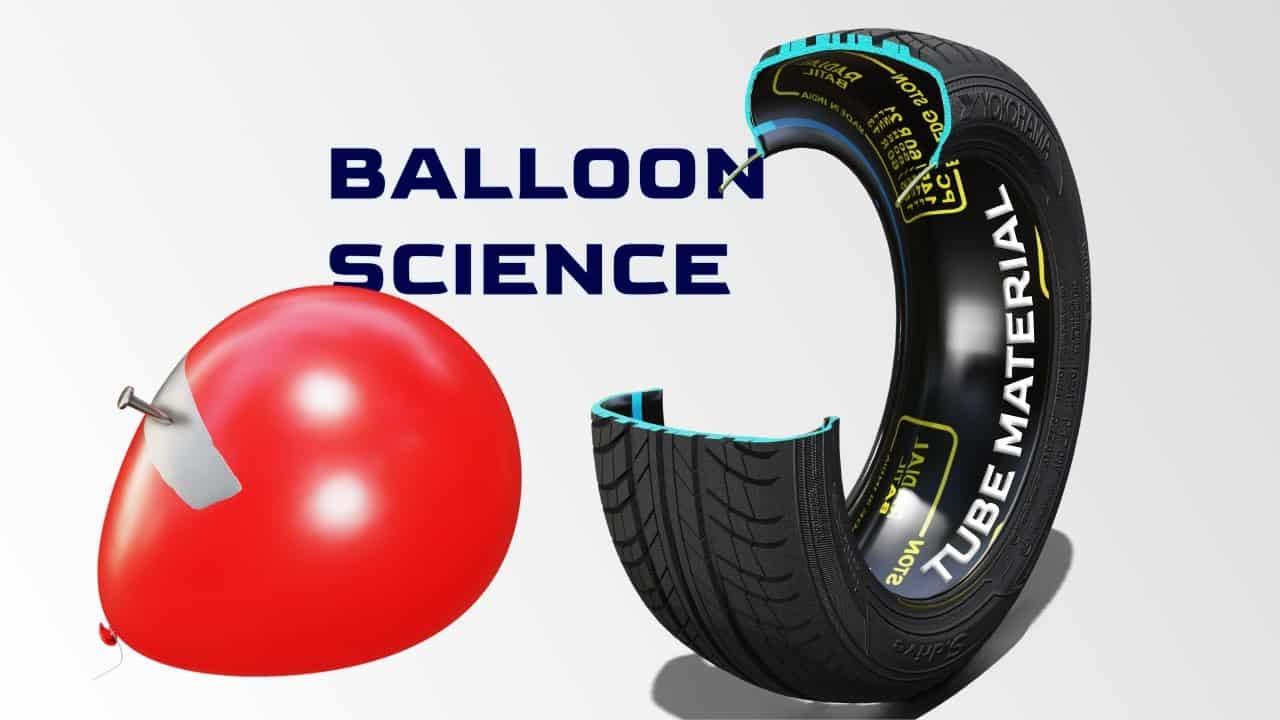

Tubeless tires are a type of tire used in vehicles that don’t require an inner tube to hold the air pressure within the tire. Unlike traditional tires, which have an inner tube to contain the air, tubeless tires have an airtight seal between the tire and the rim, keeping the air inside the tire.

Here are some key points about tubeless tires:

- Construction: Tubeless tires have an airtight inner liner that prevents air from escaping through the tire itself. The tire and the rim are designed to form a tight seal, keeping the air pressure intact.

- Advantages:

- Sealant: Some tubeless tires use a sealant, a liquid compound inside the tire, which seals punctures as soon as they occur. This helps in maintaining tire pressure and preventing air leaks.

- Compatibility: Tubeless tires require compatible rims designed to create an airtight seal. Additionally, the tire and rim need to be set up correctly for optimal performance.

- Installation: Mounting tubeless tires can be slightly more complicated than conventional tires due to the need for a proper seal between the tire and the rim. Sometimes, an air compressor is used to seat the tire bead onto the rim.

- Popular in Certain Vehicles: Tubeless tires are commonly used in bicycles, motorcycles, and increasingly in cars, trucks, and other larger vehicles due to their advantages in terms of safety and performance.

- Reduced Risk of Blowouts: Tubeless tires are less prone to sudden blowouts because there’s no tube to puncture or burst.

- Puncture Resistance: The sealant within tubeless tires can often seal small punctures automatically, reducing the likelihood of flat tires.

- Improved Heat Dissipation: Tubeless tires generally dissipate heat better, enhancing their overall performance.

Tubeless tires offer several advantages in terms of safety and convenience, especially in terms of reduced puncture risks and maintaining tire pressure. However, they require specific rims and installation techniques to function properly.